Environment

Environment Management Cell has been constituted to undertake environment protection measures and for development of all environmental aspects. For environmental sustainability, nearly 6-12% of operational cost is incurred in these measures which include maintenance and modification of Pollution Control equipment, hiring of professional consultants for various environmental studies, maintenance of sewage treatment plant, environmental and plantation works at plants & mines. The environment cell is divided in three parts:

- 1. Air Lab.

- 2. Water and waste water Lab.

- 3. Microbiological lab.

- 4. Bio-Medical Waste (BMW) for uploading.

Water and wastewater testing laboratory with advanced equipment is set-up at Jaypee Rewa Cement Complex. The water and wastewater testing is being done at Water lab. Various parameters including heavy metals are analyzed with NOVA 60 (Merck make) Spectroquant spectrometer.

A separate Air lab is in operation for the analysis of different gases i.e. SO2 & NOX as per IS: 5182. Ambient Air Quality Monitoring & Continuous Emission Monitoring Systems have been installed in the plant for on-line monitoring.

For Environment Policies, click here

Environmental Lab

Online AAQ Monitoring System Installed at Jaypee Rewa Plant

Plantation

A continual Afforestation drive in Mines, Plants & Township areas is undertaken to improve the overall environment as a safeguard against pollution. The plant species are chosen corresponding to the soil quality and locally existing variety and have a survival rate of around 80%. Upto 4,56,515 trees have already been planted in & around project site.

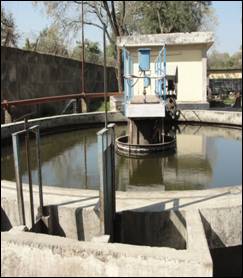

Water Conservation

The Plant is based on dry cement manufacturing process so there is no effluent released from the plant; therefore the ‘zero discharge’ principle is complied with. Moreover, the entire domestic sewage water is treated at Sewage Treatment Plant of adequate capacity upto the tertiary treatment level after which ozonation is carried out to the tertiary treated water to get rid of any odour or pathogen in the treated water. The treated water is used in the cement manufacturing process as well as for horticulture purposes.

Mines Reservoir

Six km garland canal for rain water harvesting from colony and plant premises. This harvested rain water is stored in own mines reservoir. We have 4 nos of reservoirs at mines. The total rain water harvested from colony and plant premises is stored in these reservoirs .The water from reservoirs is used in cement manufacturing process and cooling purposes.

Ecological Balance

The reclamation and rehabilitation of mined area is a continuous process in Jaiprakash Associates Limited. The overburden generated is used to back-fill the area and after imparting a good topsoil cover the area is rehabilitated in a planned way by adopting large scale Afforestation.